cv axle wont go in, Explore common CV axle installation issues, tools needed, alignment tips, and preventative measures to ensure a successful installation and avoid future problems.Cv Axle Won’t Go In: Your Comprehensive Guide

If you’re experiencing frustration with your CV axle installation, you’re not alone. Many car enthusiasts and DIY mechanics often face challenges when fitting a constant velocity (CV) axle into place. Understanding why your CV axle won’t go in is crucial for a successful installation and to ensure the proper functioning of your vehicle. In this article, we will delve into the common reasons behind installation issues, provide a detailed step-by-step guide, and outline the essential tools you’ll need for a smooth process. Additionally, we’ll share tips on achieving perfect alignment and preventative measures to keep your CV axle in top shape. Whether you’re a seasoned pro or a beginner, this comprehensive guide is designed to equip you with the knowledge you need for troubleshooting and enhancing your vehicle’s performance. Let’s get started!

Understanding Common Reasons Why Cv Axle Won’t Go In

cv axle wont go in, When encountering issues with a cv axle that won’t go in, several common reasons may be at play. Understanding these factors can help troubleshoot the problem more efficiently. Here are some of the primary reasons:

| Reason | Description |

|---|---|

| Misalignment | Improper alignment between the transmission and the axle can prevent it from inserting fully. |

| Damaged Components | Worn or damaged splines on the cv axle or differential can obstruct proper insertion. |

| Incorrect Axle Length | Using a cv axle with incorrect specifications for your vehicle may lead to fitting issues. |

| Foreign Debris | Debris in the axle housing or on the axle itself can create a barrier to proper installation. |

| Improper Technique | Using excessive force or incorrect techniques during installation can lead to complications. |

By identifying these common issues, you can take the necessary steps to address them, ensuring a smoother cv axle installation process.

Step-by-Step Guide to Diagnose Cv Axle Installation Issues

To effectively troubleshoot why your cv axle won’t go in, follow these systematic steps:

- Inspect the Axle and Transmission: Begin by examining the mating surfaces of both the cv axle and the transmission. Clean any debris or dirt that may be obstructing the proper fit.

- Check Alignment: Ensure that the cv axle is correctly aligned with the transmission. Misalignment can prevent the axle from sliding into place.

- Verify Splines: Inspect the splines on the end of the cv axle and ensure they’re not stripped or damaged. If the splines are damaged, you may need to replace the axle.

- Look for Obstructions: Check for any foreign objects, such as a retaining clip or debris inside the transmission housing that might inhibit the installation of the cv axle.

- Examine the Differential: If applicable, ensure the differential output shaft is in the proper position (for example, not fully extended) when attempting to install the cv axle.

- Evaluate the Sealing Boot: Check the sealing boot for tears or wear. A damaged boot can affect the functionality of the cv axle and its ability to seat properly.

- Confirm Compatibility: Double-check that you’re using the correct cv axle for your vehicle model and year. Incompatible parts can lead to installation difficulties.

- Consult a Repair Manual: If you’re still experiencing issues, refer to a repair manual specific to your vehicle for detailed troubleshooting steps.

By following this structured approach, you will be able to identify the most likely reasons your cv axle won’t go in and take appropriate corrective measures.

Tools Needed for Successful Cv Axle Installation

When it comes to ensuring that your cv axle installation goes smoothly, having the right tools on hand is crucial. Below is a list of essential tools that will help you throughout the installation process:

- Jack and Jack Stands: To safely lift and support the vehicle, providing access to the axle.

- Socket Set: A comprehensive set of sockets, including deep sockets, for removing and tightening bolts.

- Ratchet Wrench: This helps in effectively loosening or tightening fasteners.

- Torque Wrench: Ensures that bolts are tightened to the manufacturer’s specifications, preventing issues later on.

- Pliers: Useful for handling clips or any stubborn components you might encounter.

- Hammer: Sometimes a gentle tap is needed to dislodge stuck parts.

- Snap Ring Pliers: Essential for removing or installing snap rings that may be holding your cv axle in place.

- Grease or Lubricant: Provides lubrication during assembly and helps ease the insertion of the axle into the hub.

- Work Light: A good lighting source is beneficial, especially if you are working in a dimly lit space.

With these tools at your disposal, you’ll be well-equipped to handle the challenges of cv axle installation, ensuring a successful and efficient process.

Tips for Correctly Aligning Your Cv Axle

Ensuring that your cv axle is correctly aligned is critical for the vehicle’s performance and longevity. Here are some essential tips to help you achieve proper alignment during installation:

- Inspect the Components: Before installation, examine both the cv axle and the corresponding components for any signs of wear, damage, or debris. A clean and undamaged axle will facilitate easier alignment.

- Use the Right Tools: Utilize tools such as alignment sleeves, and sockets specifically designed for your vehicle type. These tools can help provide a precise fit and reduce the risk of misalignment.

- Check the Transmission Mount: Ensure that the transmission mount is secure and in good condition. A loose or damaged mount can affect the alignment of the cv axle.

- Align the Axle Properly: When inserting the cv axle, guide it toward the transmission while ensuring the splines match up. Avoid any forceful pushing, as this can cause misalignment.

- Verify Joint Positions: Make sure the inner and outer joints are in their proper positions before fastening. Misplacing these can lead to failure or premature wear of the axle.

- Rotate the Axle: Gently rotate the cv axle while pushing it into place. This rotation helps align the splines and can ensure a smoother fit.

- Double Check Alignment: After installation, check for any excessive axle angles or offsets. Proper alignment reduces stress on the axle and improves overall vehicle handling.

- Secure Everything: Once correctly aligned, securely fasten all bolts and clamps before testing the vehicle. A secure fit is as crucial as the proper alignment.

By following these tips, you can greatly increase the likelihood of a successful cv axle installation and avoid future alignment issues.

Preventative Measures to Avoid Future Cv Axle Problems

cv axle wont go in, To ensure the longevity and proper functionality of your cv axle, it is crucial to implement preventative measures. Here are some strategies to help you avoid future issues:

- Regular Inspections: Periodically check your vehicle’s undercarriage for any signs of wear or damage to the cv axle and its components. Look for cracks, leaks, or any signs of excessive wear.

- Proper Lubrication: Ensure that the cv axle joints are adequately lubricated according to the manufacturer’s specifications. This prevents friction and helps maintain joint mobility.

- Avoid Rough Terrain: Minimize driving on rough or uneven surfaces to reduce stress on the cv axle and other suspension components. If possible, opt for smoother routes.

- Controlled Driving: Avoid aggressive driving behaviors such as rapid acceleration, hard braking, and sharp turns. These can exert extra stress on the axles.

- Check for Alignment Issues: Regularly check your vehicle’s alignment. Misalignment can lead to uneven wear on the cv axle and other components. Address any alignment problems immediately.

- Replace Worn Parts Promptly: If you notice any deterioration in related components, such as the boots or other suspension parts, replace them as soon as possible to prevent damage to the cv axle.

- Professional Maintenance: Have your vehicle serviced by a qualified mechanic on a regular basis. Professional inspections can catch potential issues before they escalate.

By adopting these preventative measures, you can help ensure that your cv axle remains in optimal condition, reducing the chances of installation issues in the future and enhancing the overall safety and performance of your vehicle.

Frequently Asked Questions

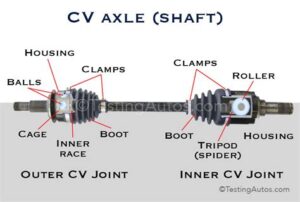

What is a CV axle?

A CV (Constant Velocity) axle is a key component of a vehicle’s drivetrain that transfers power from the transmission to the wheels while allowing for movement and flexibility in the steering.

What does it mean if a CV axle won’t go in?

If a CV axle won’t go in, it typically indicates a misalignment or obstruction that prevents it from properly connecting to the transmission or differential.

cv axle wont go in,

What are common causes for a CV axle not to fit?

Common causes include damaged splines, dirt or debris in the joint area, incorrect positioning of the axle, or issues with the transmission or differential itself.

cv axle wont go in,

How can I troubleshoot a CV axle that won’t go in?

To troubleshoot, inspect the axle and surrounding area for damage or debris, ensure the stub shaft is clean, verify alignment, and check for any obstructions that might be preventing insertion.

What tools do I need to install a CV axle?

Typically, you’ll need basic hand tools such as socket wrenches, screwdrivers, and possibly a slide hammer or pry bar for better leverage during installation.

Should I seek professional help if my CV axle won’t go in?

If you’re unsure about the installation process or if troubleshooting doesn’t resolve the issue, it’s advisable to consult a professional mechanic to avoid further damage.

Is it safe to drive with a faulty CV axle?

No, driving with a faulty or improperly installed CV axle can lead to severe vehicle damage and pose safety risks, such as loss of control.